Since the start of the First Industrial Revolution, manufacturing has been the force pushing industrial and societal transformation forward. Today, we’re in the midst of another industrial revolution, as a new generation of sophisticated technologies is transforming manufacturing into a highly connected, intelligent, and ultimately, more

productive industry. The man-powered shop floor of the past is being replaced by smart manufacturing facilities where tech-savvy workers, aided by intelligent robots, are creating the products of the future.

In this Fourth Industrial Revolution, machinery is outfitted with smart sensors to collect comprehensive, real-time data; artificial intelligence enables superhuman production efficiency and seamless quality assurance; blockchain transactions significantly expand transparency and security; edge computing assures nearly uninterrupted connectivity, and impending 5G speeds allow for ever-larger volumes of data processing from anywhere.

Modern manufacturers are no longer just makers, they are the thread that connects the entire lifecycle of a product, and to thrive in this modern environment, they must increasingly rely upon technology to power breakthrough innovations and drive more intelligent operations.

If you are a manufacturing executive or any other stakeholder and wondering how to stay ahead of the curve, we can help you with it. By attending this facilitated and hands-on workshop or an online assessment, Manufacturing stakeholders can know where they are now, their strengths and opportunities, and where they would like to go.

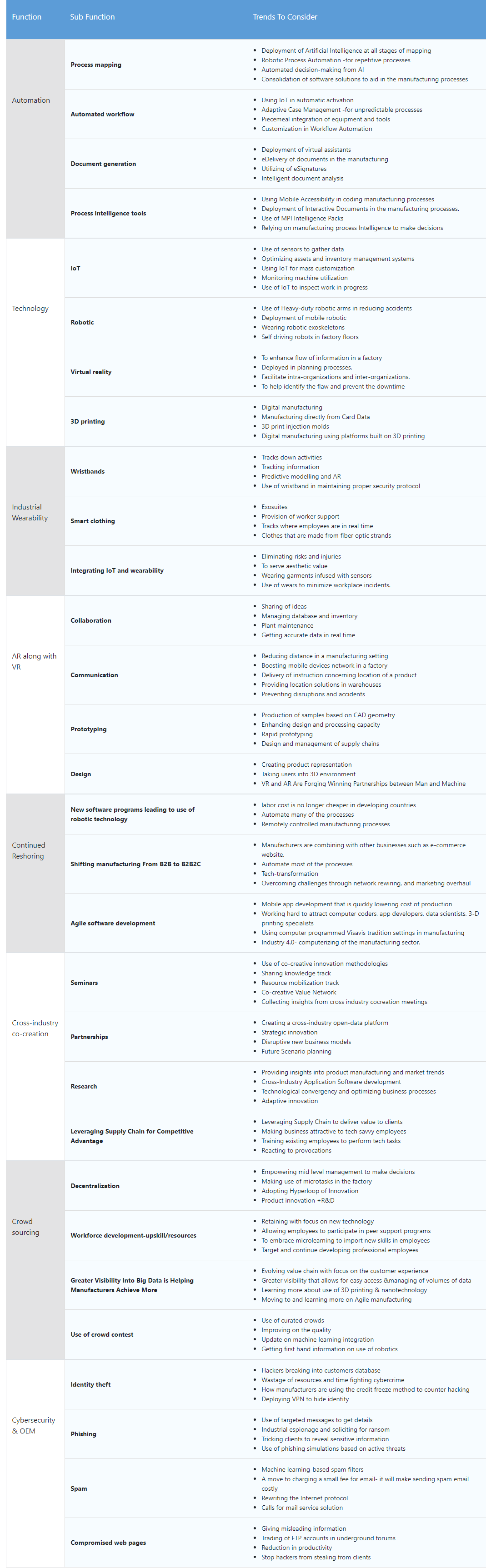

What and how we assess Manufacturing Innovation?

How the scores are calculated by our assessment?

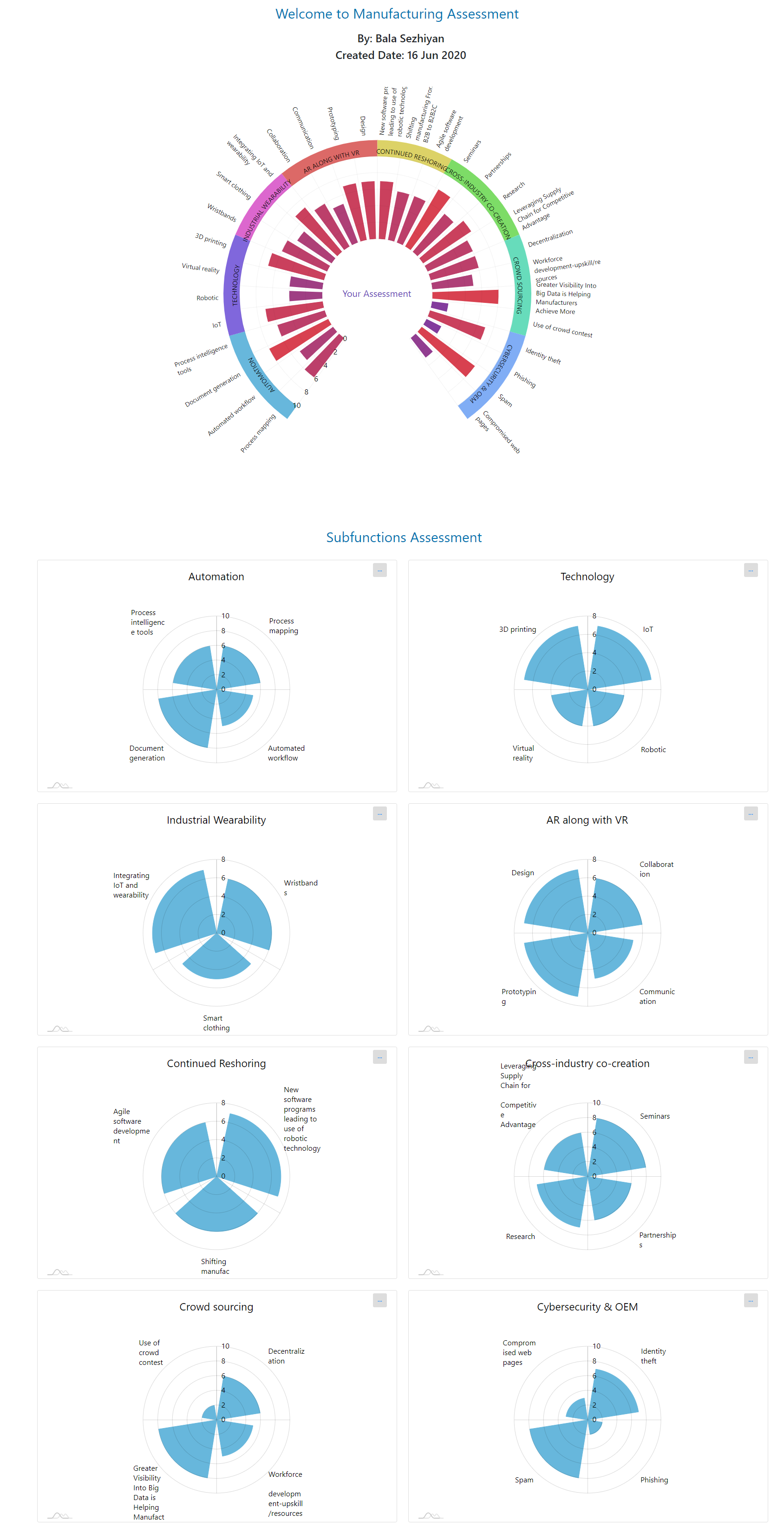

The above exercise is pretty quick. It can be completed by any stakeholder in about 15-30 minutes and results in a visual way to represent where one’s Innovation Program technology sits in comparison to industry benchmarks. Additionally, it can be completed by multiple individuals within an organization to calibrate a mutual understanding between their collective Innovation Program departments and/or other internal stakeholders. Maturity (scale of 1 to 10) is explained below.

-

- Just realized – Process not in place, however, there is a realization of the need.

- Initial (chaotic, ad hoc, individual heroics) – the starting point for use of a new or undocumented repeat process.

- Repeatable – the process is at least documented sufficiently such that repeating the same steps may be attempted.

- Defined – the process is defined/confirmed as a standard business process.

- Capable – the process is quantitatively managed in accordance with agreed-upon metrics.

- Efficient – process management includes deliberate process optimization/improvement.

- Innovator – Started challenging status-quo and incremental innovation started at the edges.

- Disruptor – The tangible impact of the innovation has been proven, started institutionalizing the sustainable.

- Market leader – You are nailing it.

- World-class – The true north of all.

And the final Report is:

** Blue bar represents Innovation Minds benchmark baselined from 25+ companies we worked with, and the black line represents where you may stand.